In the world of water treatment, a 10×54 stainless resin tank loaded is a critical component for systems that require filtration or water softening. These tanks are typically designed to hold resin media that serves to remove unwanted minerals or contaminants from water. This article will delve into the specifics of these tanks, explaining what they are, how they work, their uses, and how to maintain them for optimal performance.

What is a 10×54 Stainless Resin Tank Loaded?

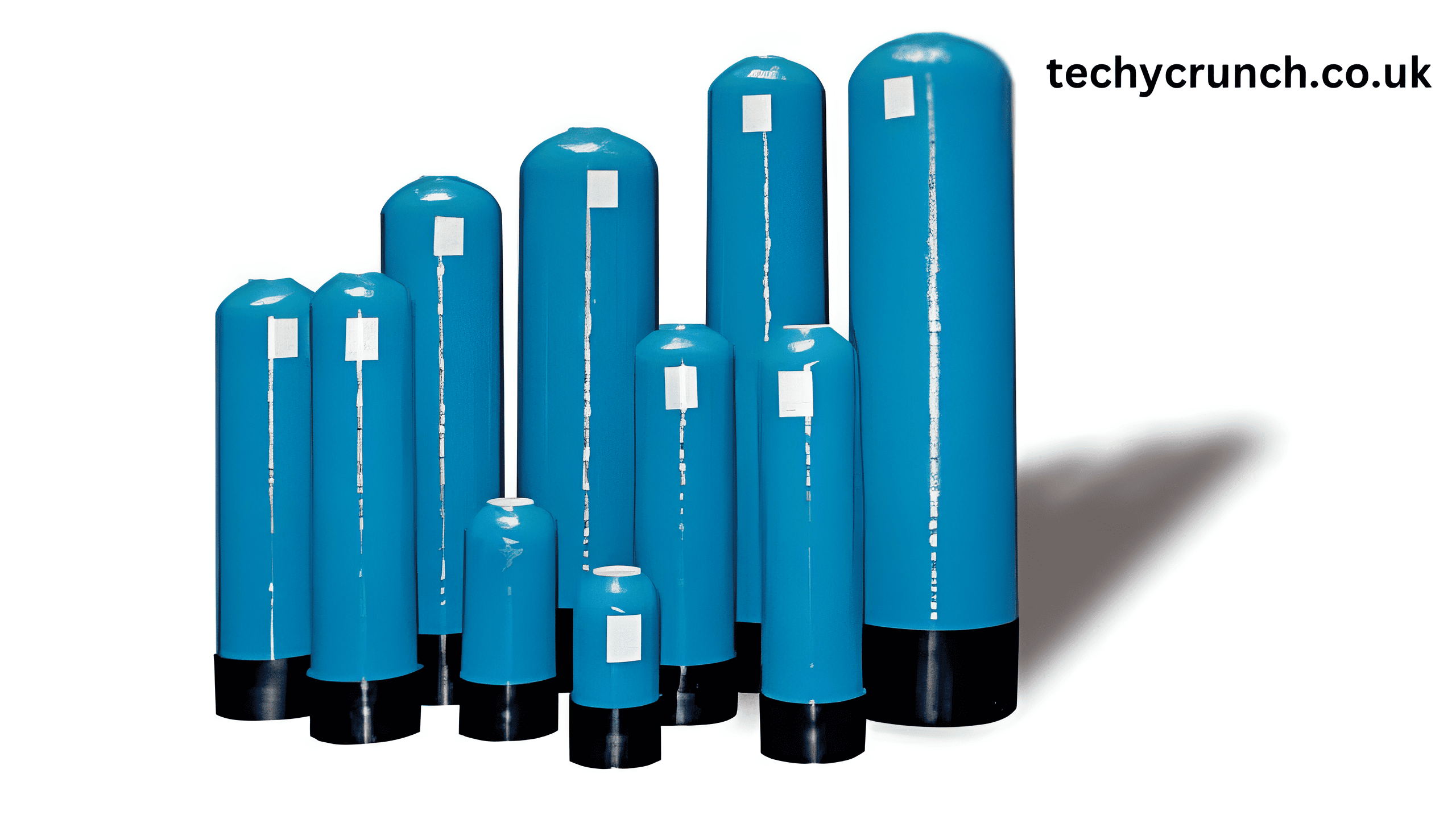

A 10×54 stain less resin tank loaded refers to a water treatment tank with specific dimensions and materials. The “10×54” designation refers to the dimensions of the tank – 10 inches in diameter and 54 inches in height. The tank is made of stainless steel, a highly durable material that resists corrosion, making it ideal for long-term use in water systems.

The term loaded means that the 10×54 stainless resin tank loaded comes pre-filled with resin media, ready to be used in water treatment processes. These resin tanks are commonly used in systems designed to soften water, remove impurities, or filter out contaminants like chlorine, fluoride, or heavy metals. The resin inside the tank plays a crucial role in removing undesirable substances from water, making it safer and more pleasant for consumption.

Key Features of a 10×54 Stain less Resin Tank Loaded

Durability and Longevity

A 10×54 stainless steel resin tank is built to last. Stainless steel is known for its resistance to rust, corrosion, and damage from chemicals. This makes the tank an excellent choice for long-term water treatment applications where tanks may be exposed to harsh conditions. Whether it’s used in industrial, commercial, or residential water systems, the durability of stainless steel ensures that the tank remains functional for years with minimal maintenance.

Efficient Water Treatment 10×54 stainless resin tank loaded

The loaded resin in these tanks is designed to quickly and effectively remove contaminants. With a 10-inch diameter and 54-inch height, the tank offers sufficient capacity for both residential and small commercial applications. The larger the surface area inside the tank, the more resin it can hold, which directly correlates to its effectiveness in treating large volumes of water. This ensures that the tank can handle high water flows without compromising its filtration abilities.

Capacity and Size

The size and capacity of a 10×54 stainless steel resin tank make it versatile and suitable for various applications. The tank can hold a significant amount of resin media, allowing it to process large quantities of water before the resin needs to be replaced or regenerated. The 10-inch diameter offers ample space for the resin, while the 54-inch height helps maximize the number of resin beads that can be packed inside the tank.

Pre-loaded for Convenience

One of the biggest advantages of purchasing a 10×54 stainless resin tank loaded is the convenience it offers. The tank comes pre-loaded with resin, eliminating the need for users to handle or install the resin themselves. This reduces setup time and ensures the resin is correctly packed into the tank, offering immediate use once installed.

The Role of Resin in Water Treatment

Resin is a type of polymer that serves as an ion-exchange material in water treatment. The resin inside the tank has special properties that allow it to attract and exchange ions. For example, in water softening applications, the resin beads attract calcium and magnesium ions (the minerals responsible for water hardness) and exchange them for sodium ions. This process significantly reduces the hardness of water.

Resins can also be designed to remove other contaminants from water, such as iron, chlorine, or specific heavy metals. In these cases, the resin’s function is to “trap” or exchange unwanted particles, effectively purifying the water.

Types of Resin Used in These Tanks

There are several types of resins used in water treatment, and the type of resin loaded in the tank will depend on the application. Some common types include:

Cation Exchange Resin: Primarily used in water softening applications, this resin exchanges calcium and magnesium ions for sodium or potassium ions.

Anion Exchange Resin: This type of resin is used to remove negatively charged contaminants such as chlorides, nitrates, or sulfates.

Mixed-Bed Resin: A combination of both cation and anion exchange resins, often used for ultra-pure water production.

Iron Removal Resin: Specifically designed to remove iron and manganese from water.

Each type of resin has unique properties and is chosen based on the water treatment system’s requirements.

Applications of a 10×54 Stainless Resin Tank Loaded

These tanks have a wide range of applications, especially in water treatment processes.

Water Softening

Water softening is the most common application for resin tanks. Hard water, which contains high levels of calcium and magnesium, can cause problems such as scale buildup in pipes and appliances. A resin tank loaded with cation exchange resin helps to remove these minerals, replacing them with sodium or potassium ions. This process improves the quality of water, making it more suitable for drinking, cleaning, and bathing.

Iron and Manganese Removal

Many residential and industrial water supplies contain elevated levels of iron and manganese. These minerals can cause staining in appliances, laundry, and even in the water itself. A 10×54 stainless resin tank loaded with a specific type of resin designed to remove iron and manganese can help address this problem. The resin traps these metals and removes them from the water, ensuring clean, clear water for everyday use.

Reverse Osmosis (RO) Pre-treatment

Before water undergoes reverse osmosis filtration, it often goes through a softening process. This helps to protect the reverse osmosis membranes from scaling and ensures better performance of the RO system. A resin tank can be used as a pre-treatment step in this process, removing hardness and other contaminants before the water enters the RO unit.

Deionization (DI) Systems

Deionization is a method used to remove all ions from water, including salts and minerals. This is particularly important in industries that require ultra-pure water for manufacturing, laboratory applications, or medical uses. A 10×54 stainless resin tank, loaded with mixed-bed resin, can be used to achieve this level of purity by exchanging all ions present in the water.

Chlorine and Chemical Removal

Certain types of resin can also remove chlorine and other chemicals that may be present in water. This is important for improving the taste and odor of water, as well as for ensuring that it is safe for consumption or use in industrial processes.

Installation and Maintenance of a 10×54 Stainless Resin Tank Loaded

Installation

Installing a 10×54 stain less resin tank loaded is relatively straightforward but should be done carefully to ensure optimal performance. Below are the key steps involved in installation:

Placement: Position the tank in a location that provides easy access for maintenance and that is near the water supply lines.

Connecting Inlet and Outlet: Attach the water supply lines to the tank’s inlet and outlet valves. These valves are usually located at the top and bottom of the tank.

Bypass Valve: If your system includes a bypass valve, install it to allow the flow of water to be diverted around the tank when necessary.

Pressure Check: After everything is connected, check the system for leaks and ensure that the water pressure is within the recommended range for the tank.

Regeneration System: If your system includes a regeneration feature, ensure that the regeneration cycle is set up correctly. This may involve connecting brine tanks or other regeneration equipment.

Maintenance

Maintaining a 10×54 stainless resin tank loaded is essential to ensure the longevity and efficiency of the water treatment system.

Resin Regeneration

Over time, the resin beads will become saturated with the ions they have removed from the water. Regeneration is the process of flushing the resin with a brine solution to restore its ion-exchange capacity.

Cleaning and Sanitizing

Regularly inspect and clean the tank to prevent the buildup of minerals, algae, or bacteria. Use mild cleaning agents and rinse thoroughly.

Resin Replacement

While resin can last for several years with proper care, it will eventually need to be replaced. The frequency of replacement depends on the water quality and the amount of water processed. Resin replacement can be done by a professional or according to the manufacturer’s instructions.

System Inspections

Periodically inspect the entire water treatment system, including the tank, valves, and connections.

Conclusion

The 10×54 stainless resin tank loaded is a versatile and essential component for water treatment systems. Whether used for water softening, chemical removal, or other filtration processes, it plays a critical role in improving the quality of water. With its durable stainless steel construction, efficient resin media, and ease of use, it is a reliable choice for both residential and commercial applications.

Proper installation and maintenance are key to ensuring that the system performs optimally over its lifespan. With the right care, a 10×54 stainless resin tank can provide years of reliable water treatment, ensuring clean, safe, and soft water for all your needs.