Understanding the Vr9205q1010 0151M00014 low Adjustment Screw

In the world of electronics, precision and fine-tuning are key factors in ensuring devices operate efficiently. One of the crucial components in certain electronic devices, particularly those involved in voltage regulation or signal control, is the vr9205q1010 0151m00014 low adjustment screw. These screws are used to fine-tune the performance of a device to match specific requirements. The VR9205Q1010 and 0151M00014 are two specific models that feature low adjustment screws, and understanding how to adjust them can be critical for optimal device performance.

This article will delve into the specifics of these models, their functionality, and the importance of proper screw adjustments for effective performance. It will also cover how to safely adjust these screws, potential risks involved, and provide tips on maintaining the devices that house them.

What is a vr9205q1010 0151m00014 low adjustment screw?

A low adjustment screw is a component used in electronic devices to fine-tune the performance of circuits or sensors. In most cases, these screws are part of a potentiometer or similar device that regulates voltage or current. By adjusting the screw, users can modify the output of the circuit, typically lowering it to a desired level. This adjustment helps achieve precise calibration for optimal device performance.

The vr9205q1010 0151m00014 low adjustment screw is commonly used in devices that require fine-tuning for different operating conditions. For example, in voltage regulators or audio equipment, the low adjustment screw is crucial for setting base levels, ensuring that the device operates within a specified range.

The Role of the VR9205Q1010 and 0151M00014

The VR9205Q1010 and 0151M00014 are part numbers often associated with specific components or devices that include a low adjustment screw. These models might refer to voltage regulators, potentiometers, or other precision-adjustable devices. Let’s break down each model to understand its context and the role of the low adjustment screw.

VR9205Q1010

The VR9205Q1010 is a specific part number often used to identify a voltage regulator or a potentiometer that includes the ability to adjust the low output. Voltage regulators are critical components used in various electronics to maintain a constant output voltage regardless of input fluctuations. Devices that rely on consistent voltage for performance, such as audio amplifiers or sensors, benefit from having the ability to fine-tune this output.

The vr9205q1010 0151m00014 low adjustment screw model allows for minor adjustments to the voltage output. This fine-tuning helps ensure that the device operates at optimal levels, even if environmental factors cause fluctuations in power supply or demand. The screw typically works in conjunction with other adjustment mechanisms within the device to balance performance and prevent over-voltage or under-voltage scenarios.

0151M00014

Similarly, the 0151M00014 part number likely corresponds to another device or component that features a low adjustment screw. This could be a different model of voltage regulator, sensor, or power supply unit that requires precise calibration. Like the VR9205Q1010, the adjustment screw is used to fine-tune the device’s output, ensuring it stays within a specified range for optimal operation.

Devices that include a low adjustment screw often feature a potentiometer or trim pot, which enables users to make very small adjustments to the output. The 0151M00014 model is designed to facilitate such fine-tuning, which is essential for equipment in industries like telecommunications, broadcasting, and even in consumer electronics where stable and accurate performance is crucial.

The Functionality of the vr9205q1010 0151m00014 low adjustment screw

The low adjustment screw is often part of an overall system designed for precise electronic control.

Voltage Control

In voltage regulators or power supply units, the low adjustment screw helps control the output voltage. By rotating the screw, users can lower the output voltage to match specific requirements. For instance, in systems that need to maintain a voltage within a tight range, this screw allows for fine adjustments. Ensuring that the output voltage remains stable can prevent damage to sensitive components in the device.

Signal Regulation

In devices like audio equipment or signal processing units, the low adjustment screw regulates the signal strength or volume. This function is particularly important in high-fidelity audio systems, where minor variations in signal levels can affect the overall sound quality. The low adjustment screw enables users to set a baseline signal level and then adjust it according to the system’s needs.

Calibration and Precision Tuning

Both the VR9205Q1010 and 0151M00014 models are likely used in scenarios that demand calibration and precision tuning. Whether it’s for maintaining stable voltage or regulating signal levels, the vr9205q1010 0151m00014 low adjustment screw provides a means for ensuring that the system remains within specified tolerances. This is especially useful in environments where performance consistency is critical, such as in scientific equipment or medical devices.

How to Adjust the Low Adjustment Screw

Adjusting the low adjustment screw on models like the VR9205Q1010 or 0151M00014 requires precision and care. It’s important to understand the best practices for making these adjustments to avoid damaging the device or affecting its performance. Below are step-by-step instructions on how to safely adjust these screws.

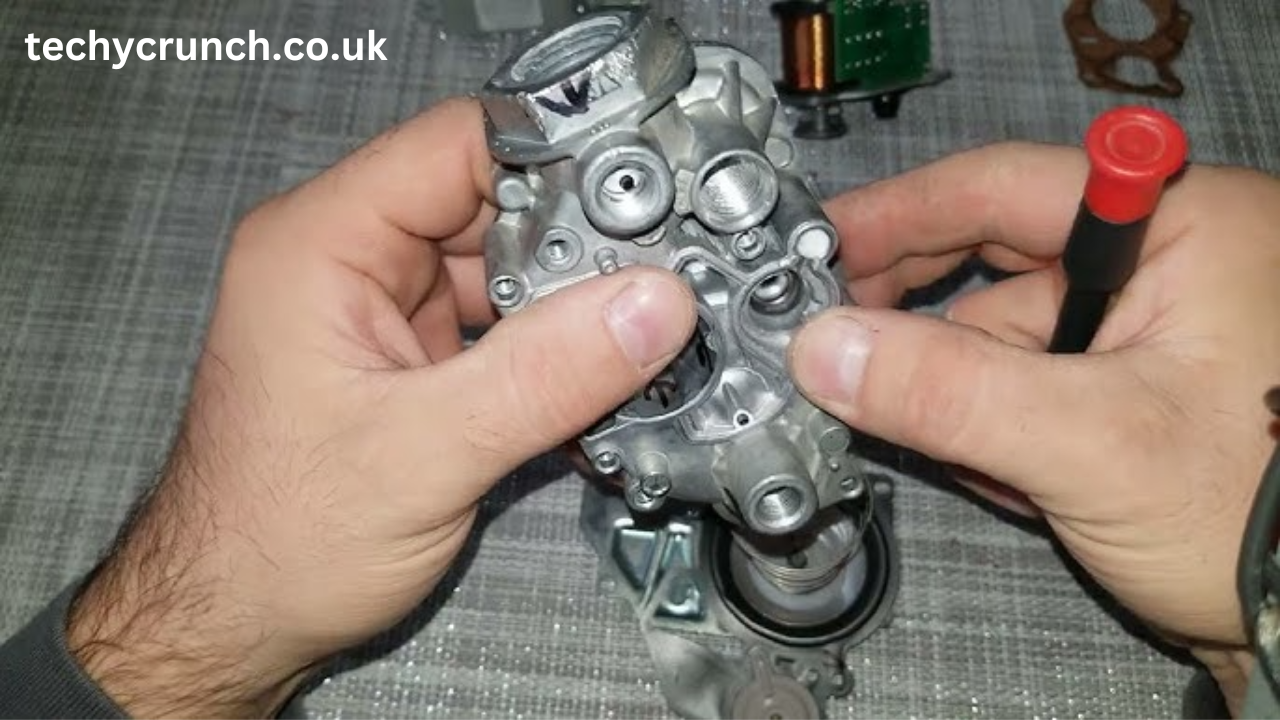

Identify the Screw

First, locate the low adjustment screw on the device. Depending on the model, it might be marked with a label or symbol. In most cases, it will be a small screw near the potentiometer or voltage regulation section of the device.

Use the Right Tools

Usually, a small flathead screwdriver is required to turn the screw. Ensure that the tool fits the screw snugly to avoid slipping and potentially damaging the device.

Power Down the Device

Before making any adjustments, power down the device and ensure it is disconnected from any power sources. This is an important safety step to avoid electrical shocks or shorts while working on the internal components.

Make Small Adjustments

Turn the low adjustment screw slowly and gently. It’s important to make small adjustments at a time, as this will give you greater control over the output. Turn the screw clockwise to increase the setting or counterclockwise to decrease it. The precise effect will depend on the specific model and what you’re adjusting, but generally, these screws are designed to make very fine changes.

Test the Output vr9205q1010 0151m00014 low adjustment screw

After making an adjustment, turn the device back on and check the output. This may involve measuring the voltage with a multimeter or testing the signal quality with appropriate equipment. If the device is not functioning within the desired parameters, turn off the device and make further adjustments as needed.

Final Calibration

Once the desired output level is achieved, finalize the calibration. Some devices may require additional fine-tuning to achieve perfect performance, especially if they will be used in critical applications.

Common Issues with Low Adjustment Screws

While low adjustment screws are vital for precision tuning, they can sometimes lead to issues if not handled correctly.

Over-Tightening

Over-tightening the low adjustment screw can damage the internal components or make it impossible to adjust properly. Always turn the screw gently and avoid applying excessive force.

Misalignment

Improper adjustment can lead to misalignment, where the device doesn’t function as intended. Always ensure you follow the manufacturer’s guidelines for adjustment, especially if the device is complex or has multiple controls.

Wear and Tear

With regular adjustments, the vr9205q1010 0151m00014 low adjustment screw may experience wear, leading to rough or imprecise operation. If the screw starts to feel less responsive, it may need to be replaced or maintained.

Best Practices for Maintaining the Adjustment Screw

To ensure the longevity and proper functioning of the low adjustment screw, consider the following maintenance tips:

- Regular Inspection: Periodically inspect the screw for signs of wear or damage.

- Clean the Area: Keep the screw and surrounding areas clean to avoid dirt and debris from affecting the adjustment.

- Use Appropriate Tools: Always use the correct tools for adjustments to prevent damaging the screw or surrounding components.

- Avoid Over-Adjustment: Make only small, gradual adjustments to avoid stressing the components.

Conclusion

The vr9205q1010 0151m00014 low adjustment screw, are essential for achieving optimal performance in electronic systems. Whether adjusting voltage levels or regulating signals, these screws provide a means of precise control that can make a significant difference in device functionality.

By understanding how to properly adjust these screws and maintaining the devices that house them, users can ensure that their equipment remains reliable and effective. Proper calibration through low adjustment screws is not just about enhancing performance; it’s about making sure the device functions correctly in all conditions, delivering the expected results every time.